2025 SHINI innovate to secure a large order of mould temp. controllers

Recently, exciting news came that Dongguan Shini successfully received an order for over 5000 mould temperature controllers from an automotive enterprise. This significant breakthrough not only manifests Shini's technological strength and market competitiveness in mould temperature controllers but also marks a substantial increase in our business volume. This order is a testament to our remarkable technological innovation, customer service, and branding achievement. The following is a detailed analysis of how Shini achieved this brilliant achievement through technological innovation.

Technology Innovation: The key to core competitiveness

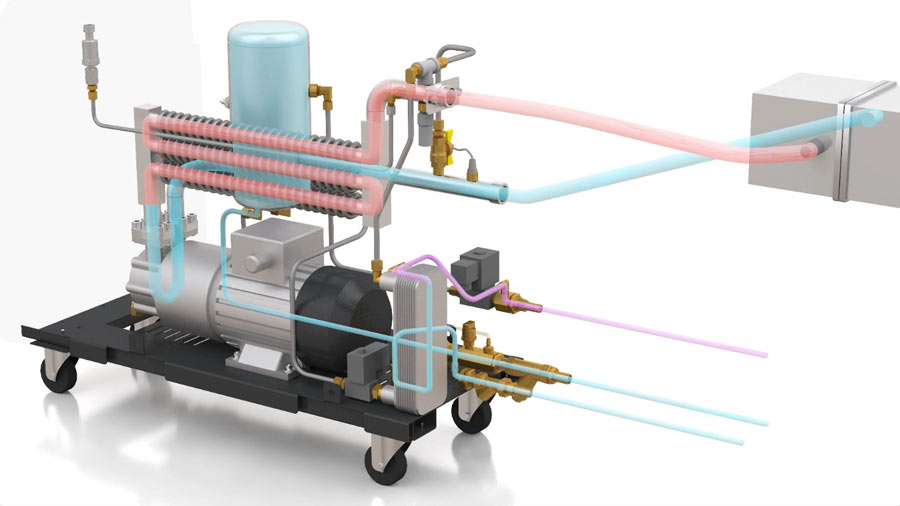

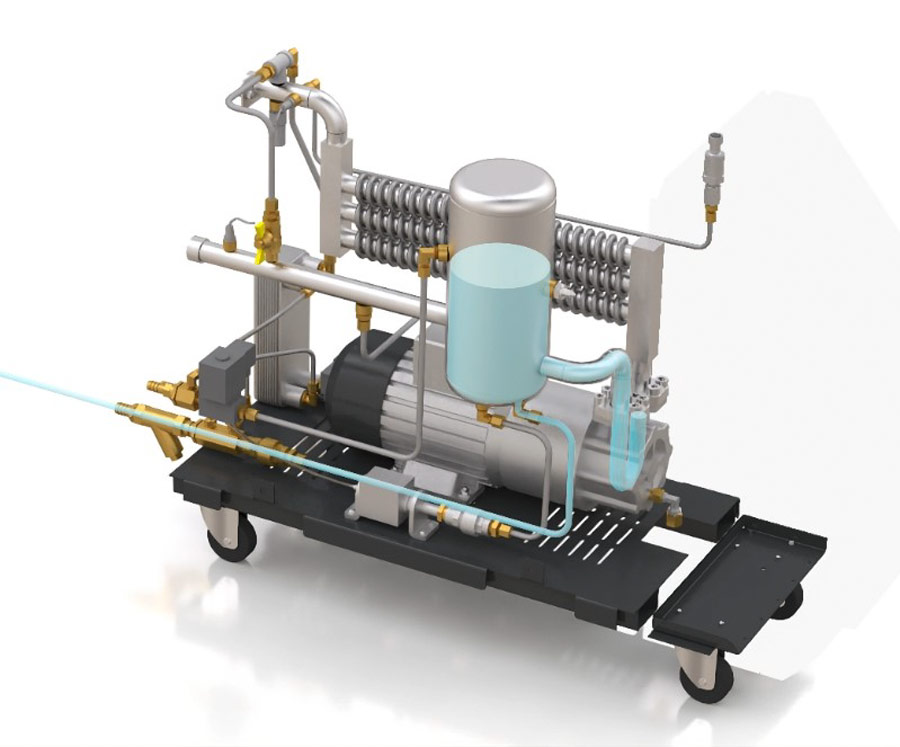

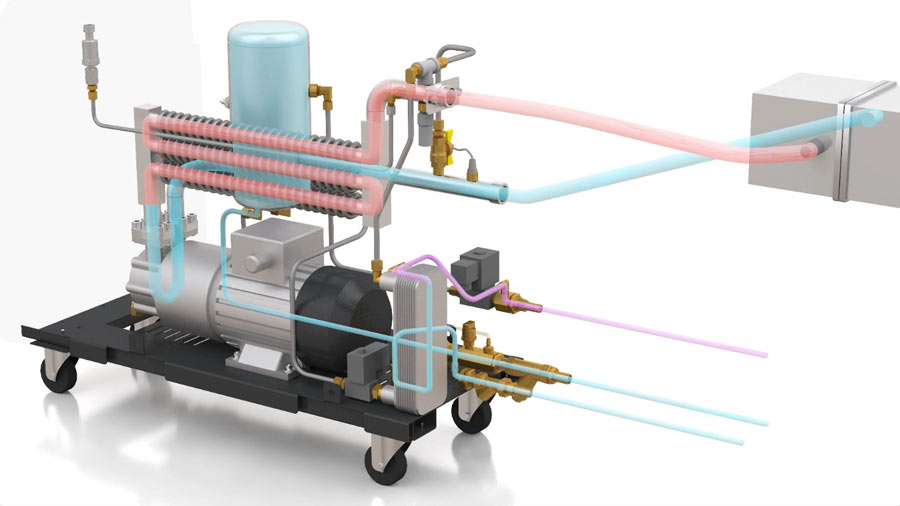

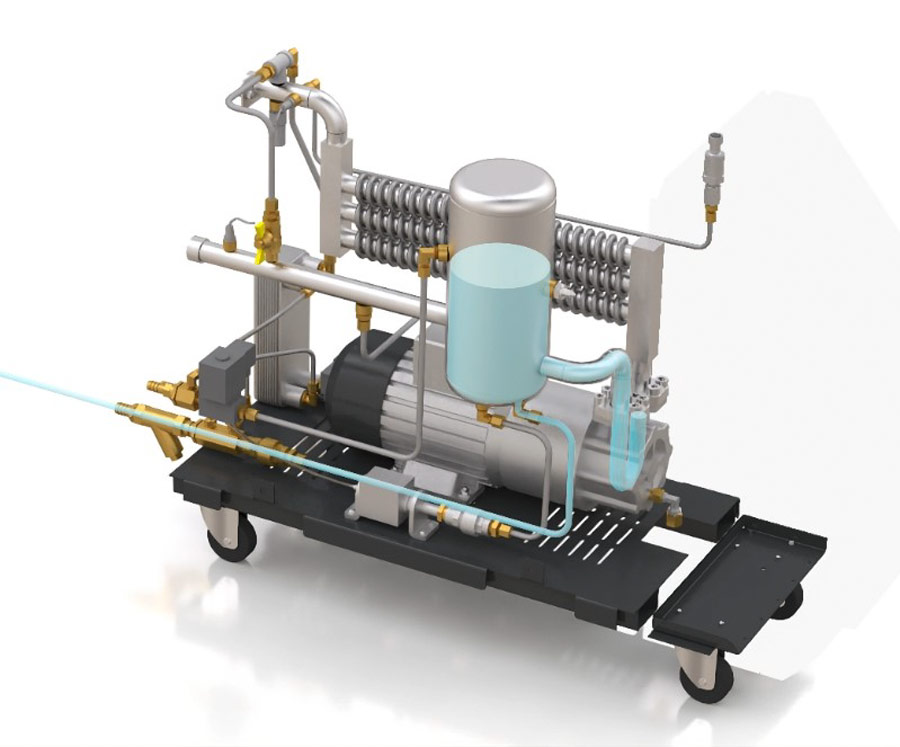

1. Excellent heating technology

Shini adopts the indirect heating technology in the Mould Temperature Controller to solve the common issue of scales in conventional heating methods. This innovative solution not only vastly reduces the scale's impact on the heater's service life but also significantly reduces its high requirement for water quality, thus improving the overall performance and reliability of the equipment. The indirect heating technology also enhances energy efficiency, reducing operational costs for our customers.

2. Precise temperature control

One of the key functions of the Mould Temperature Controller is to control the mould temperature precisely to ensure stable production and consistent product quality. Shini Mould Temperature Controller is equipped with a high-precision sensor and control system that can achieve accurate temperature control within the range of ±0.5℃. This high-temperature stability is vital for parts processing with extremely high-quality requirements in automotive manufacturing.

3. Magnetic-Drive Technology

To enhance the reliability of the Mould Temperature Controller, which can reach temperatures of 180℃ or even higher, Shini has incorporated a magnetic-driven pump technology within the unit. This technology uses magnetic fields to transmit power, eliminating the leakage issues associated with traditional mechanical seals. As a result, it not only enhances the system's overall efficiency but also improves safety.

4. Adaptive pressure and safety protection technology

The adaptive adjustment mechanism enhances equipment safety and extends its service life without compromising production efficiency. Additionally, it activates immediately upon detecting abnormal pressure or when the pressure reaches a preset safety threshold, ensuring that pressure returns to a safe range. Furthermore, the system includes multiple protection mechanisms, such as protection against low liquid levels, overheating, and overload. These features allow for a prompt response to various abnormal situations, helping to prevent accidents and ensuring safe production.

Personal customized service

The production technique and demand vary from customer to customer, and Shini fully understands this point and provides customized solutions. According to the requirements of this automotive manufacturer, Shini has devised a complete set of mould temperature controller systems for it, covering various demands from standard equipment to unique configurations to ensure system compatibility and scalability.

Premium customer service:Establish long-term cooperative relationships

From the project's early stage of technical consultation to later-stage debugging on-site, Shini can provide customers with one-stop technical support. This comprehensive support, backed by our global service network and experienced after-sales engineer and technical support team, ensures that our customers can rely on us for any technical issues that may arise. This commitment to customer service is key to ensuring continuous production and customer satisfaction.

Brand Influence: Win the customer trust

As a leader in plastic materials handling equipment, Shini has established a good reputation and brand image in the industry with over 50 years of technological and marketing experience. With the help of this large order, Shini further consolidates its leading position in the market. Shini will always regard technological innovation as the core driving force for development, continuously enhance the research and development inputs, and collaborate with more scientific research institutions and universities to make leading-edge technical studies.

Technology Innovation: The key to core competitiveness

1. Excellent heating technology

Shini adopts the indirect heating technology in the Mould Temperature Controller to solve the common issue of scales in conventional heating methods. This innovative solution not only vastly reduces the scale's impact on the heater's service life but also significantly reduces its high requirement for water quality, thus improving the overall performance and reliability of the equipment. The indirect heating technology also enhances energy efficiency, reducing operational costs for our customers.

2. Precise temperature control

One of the key functions of the Mould Temperature Controller is to control the mould temperature precisely to ensure stable production and consistent product quality. Shini Mould Temperature Controller is equipped with a high-precision sensor and control system that can achieve accurate temperature control within the range of ±0.5℃. This high-temperature stability is vital for parts processing with extremely high-quality requirements in automotive manufacturing.

3. Magnetic-Drive Technology

To enhance the reliability of the Mould Temperature Controller, which can reach temperatures of 180℃ or even higher, Shini has incorporated a magnetic-driven pump technology within the unit. This technology uses magnetic fields to transmit power, eliminating the leakage issues associated with traditional mechanical seals. As a result, it not only enhances the system's overall efficiency but also improves safety.

4. Adaptive pressure and safety protection technology

The adaptive adjustment mechanism enhances equipment safety and extends its service life without compromising production efficiency. Additionally, it activates immediately upon detecting abnormal pressure or when the pressure reaches a preset safety threshold, ensuring that pressure returns to a safe range. Furthermore, the system includes multiple protection mechanisms, such as protection against low liquid levels, overheating, and overload. These features allow for a prompt response to various abnormal situations, helping to prevent accidents and ensuring safe production.

Personal customized service

The production technique and demand vary from customer to customer, and Shini fully understands this point and provides customized solutions. According to the requirements of this automotive manufacturer, Shini has devised a complete set of mould temperature controller systems for it, covering various demands from standard equipment to unique configurations to ensure system compatibility and scalability.

Premium customer service:Establish long-term cooperative relationships

From the project's early stage of technical consultation to later-stage debugging on-site, Shini can provide customers with one-stop technical support. This comprehensive support, backed by our global service network and experienced after-sales engineer and technical support team, ensures that our customers can rely on us for any technical issues that may arise. This commitment to customer service is key to ensuring continuous production and customer satisfaction.

Brand Influence: Win the customer trust

As a leader in plastic materials handling equipment, Shini has established a good reputation and brand image in the industry with over 50 years of technological and marketing experience. With the help of this large order, Shini further consolidates its leading position in the market. Shini will always regard technological innovation as the core driving force for development, continuously enhance the research and development inputs, and collaborate with more scientific research institutions and universities to make leading-edge technical studies.